Products

Dearation/Granulation/Pressing

- Mining/Ceramics/Glass

- Metal/Battery/Semiconductor

- Foodstuff/Agriculture/Recycle

- Pharmaceuticals/Cosmetics

Roll Granulator

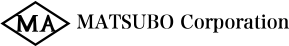

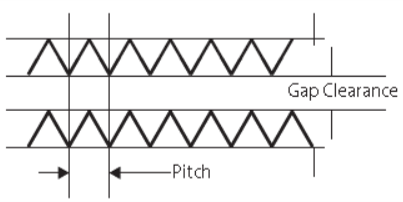

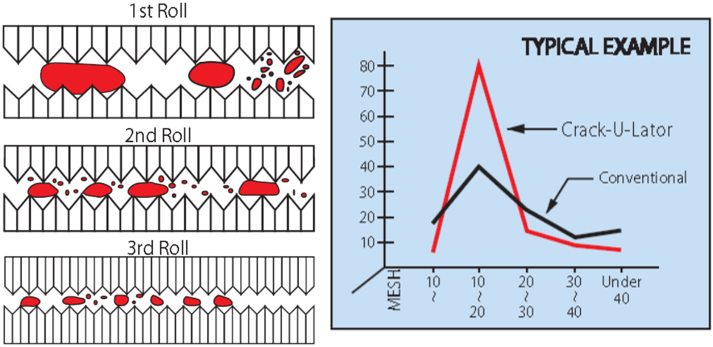

The Roll Granulator cracks material between two corrugated rollers. Each peak on the roller acts as a fulcrum point that cracks each particle as it is bridged between the mating roller. The material then pass through succeeding sets of rollers that can be arranged with narrower pitch and clearance, and more stages to arrive at finer and finer particles.

Movie

Features

-

1.Overgrinding is kept low using a cracking process resulting in very few fines. The result is a sharp particle size distribution.

2.The roller teeth do not actually touch one another and contact between the rollers and material is brief. Therefore almost no static electricity is generated.

3.There is no heat generation or wear on the roller surface even if the roll granulator is run continuously.

4.Particle size distribution is sharper than conventional grinders (hammer, grinding mill, oscillator).

5.Unlike the granulation method, middle processes i.e. dampening, mixing and drying processes have been eliminated, and efficient granulation is performed in a single unit.

6.The height and the installation area per throughput is considerably less than other dry process granulators.

Applications

1.Pharmaceuticals: Granules, Granules for powdered medicines, Particle size adjustment before tablet press, Recovery of tablets from film coating, Recovery of powder from capsules

2.Phenol resins, Epoxy resins

3.Grinding and granulating Detergents, Fertilizers, Agricultural chemicals

4.Grading Granular activated charcoals

5.Granulating Absorbent polymers

6.Grinding Coffee, Peanuts, Almonds, Spices, Freeze-dried foods, etc.

We also have other models available that are not shown here. Contact us for details.

Specifications

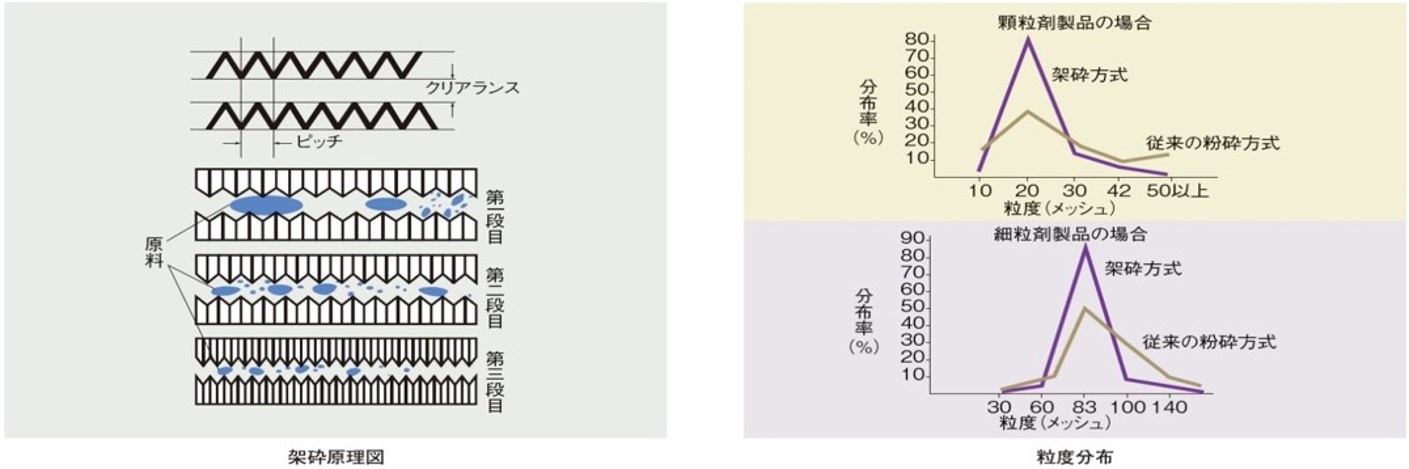

・Metal parts in contact with product are made of stainless steel SUS304, except for grinding rolls with hard chromium plating over the surface.

・The number of grinding stages can be chosen depending on the grinding purpose from 1 stage up to 6 stages.

・Vibrating feeder is included.

・Water-cooling rolls can be chosen optionally.

Specifications

| Model | Size of roll (φ x L) | Number of rolls | Capacity (kg/h) | Motor (kW) | Weight (kg) | Dimensions (W x L x H) |

|---|---|---|---|---|---|---|

| GRN-T53S | 115 x 50mm | 6 | 25 | 0.75 | 300 | 600 x 500 x 1,000mm |

| GRN-1031 | 115 x 100mm | 6 | 50 | 1.5 | 500 | 600 x 500 x 1,000mm |

| GRN-1531 | 115 x 150mm | 6 | 75 | 1.5 | 600 | 700 x 500 x 1,000mm |

| GRN-2531 | 115 x 250mm | 6 | 125 | 1.5 | 700 | 800 x 500 x 1,200mm |

| GRN-3531 | 120 x 350mm | 6 | 185 | 2.2 | 1,000 | 1,470 x 700 x 2,000 |

| GRN-4531 | 150 x 450mm | 6 | 300 | 3.7 | 1,300 | 1,750 x 800 x 2,100 |

| GRN-6031 | 150 x 600mm | 6 | 400 | 3.7 | 1,500 | 1,900 x 800 x 2,350mm |

| GRN-8031 | 200 x 800mm | 6 | 700 | 5.5 | 1,800 | 2,100 x 1,000 x 2,550mm |

| GRN-10031 | 250 x 1,000mm | 6 | 1,000 | 7.5 | 2,000 | 2,300 x 1,200 x 2,750mm |