Products

Classifying/Screening

- Mining/Ceramics/Glass

- Toner

- Metal/Battery/Semiconductor

- Foodstuff/Agriculture/Recycle

- Pharmaceuticals/Cosmetics

- Paper/Pulp

FS Hi-Sifter

Unlike conventional vibrating sieve machines, it uses two vibration motors to generate strong vertical vibrations for sieving.

Strong vertical vibration allows sieving with fine openings without screen blinding, without using tapping balls or ultrasonic devices.

This technology can avoid the contamination from the balls nor expensive and difficult maintenance of exchanging ultrasonic devices.

Features

-

・Classifies without screen blinding due to strong vertical vibration

・Capability equivalent to or better than ultrasonic vibrating sieves

・Tension management less mesh design allows users to easily replace commercially available inexpensive wire mesh or nylon mesh

・Prevents contamination as tapping balls are not used.

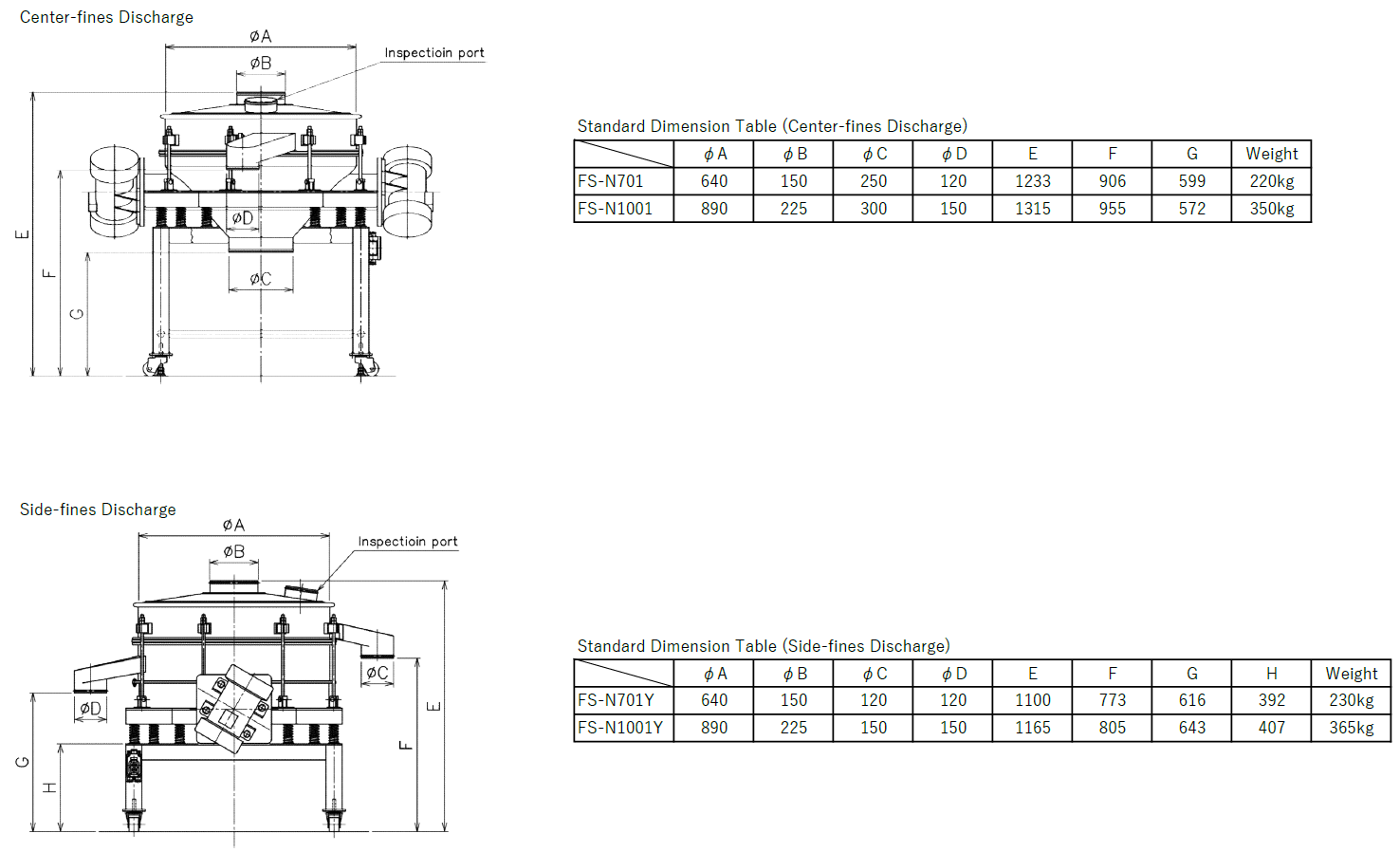

・For the discharge method, select side fine discharge type or center fine discharge type

・Sanitary specifications required for pharmaceuticals and food products

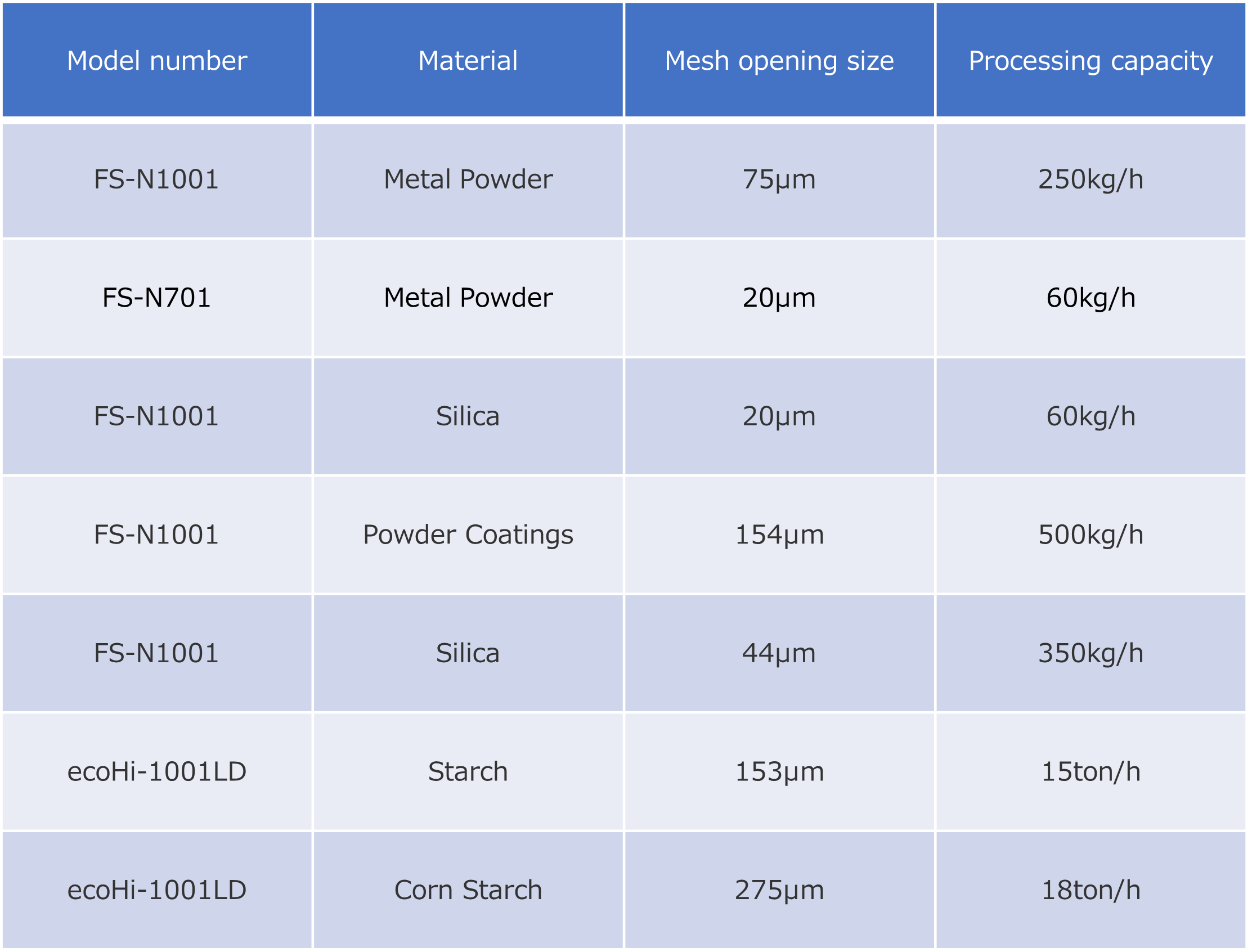

・For food products (flour, starch, etc.) and larger opening size application, the sister model Eco-Hi Sifter is available, which achieves tons/h of mass processing of scalping by applying strong horizontal vibration.

Applications

Inorganic powder: metal powder, metal oxide, ceramic, carbon, silica, etc.

Resin powder: thermoplastic resin, thermosetting resin, engineering plastic, etc.

Pharmaceuticals: APIs, excipients, herbal medicines, herbal extracts, etc.

Food: flour, starch, cornstarch, spices, powdered oil, powdered milk, etc.

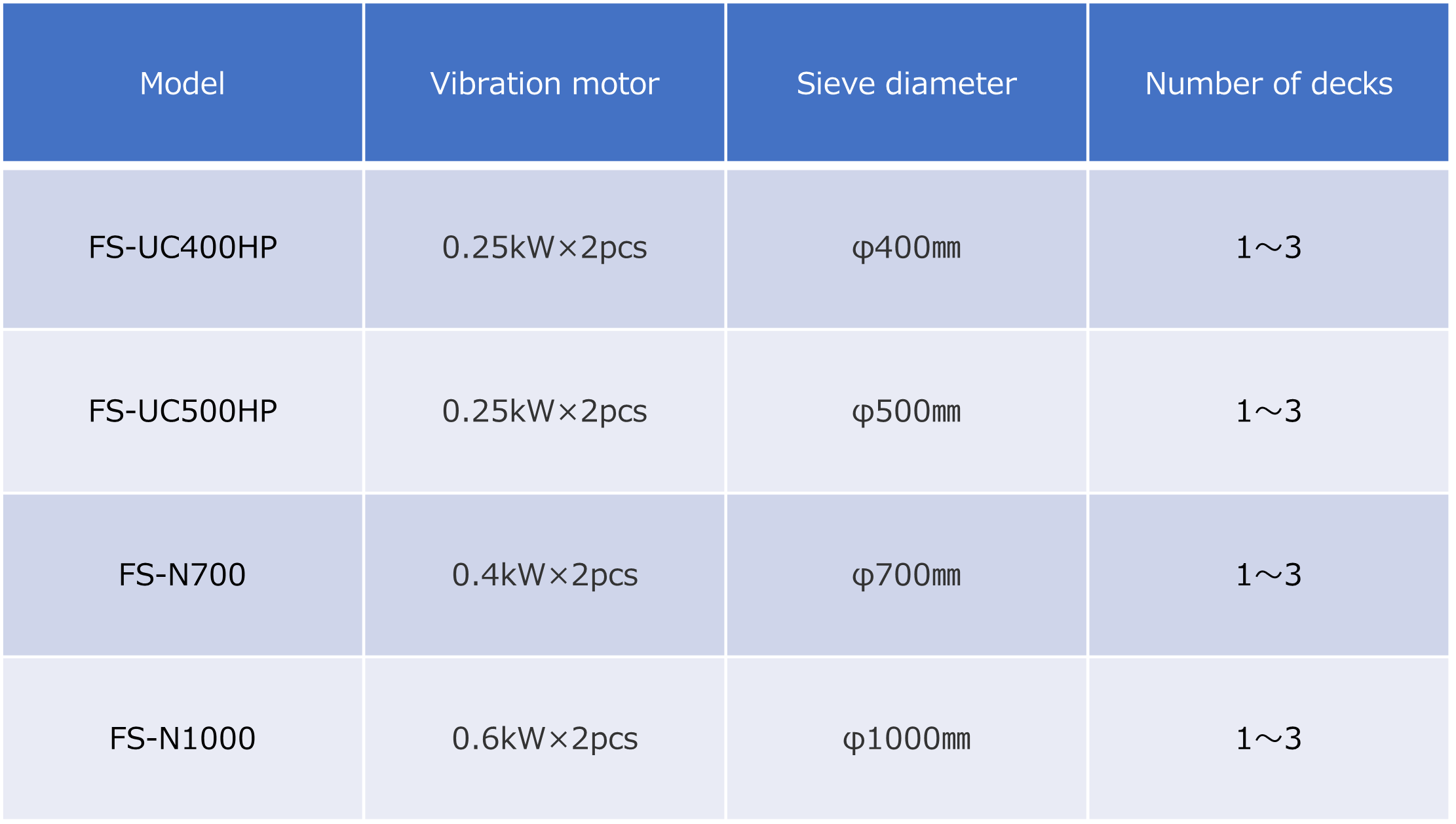

Specifications

・Material: Standard is 304 Stainless Steel for powder contact part. All parts stainless steel as an option.

・Fine powder discharge: Center fine discharge type and Side fine discharge type

・Packing: Standard material is chloroprene, optionally silicone and EPDM are available.

・Auxiliary equipment: raw material feeders, etc.

Applications

・Inorganic powder: metal powder, metal oxide, ceramic, carbon, silica, etc.

・Resin powder : thermoplastic resin, thermosetting resin, engineering plastic, etc.

・Pharmaceuticals : APIs, excipients, herbal medicines, herbal extracts, etc.

・Food : flour, starch, cornstarch, spices, powdered oil, powdered milk, etc.

Specifications

・Material: Standard is 304 Stainless Steel for powder contact part. All parts stainless steel as an option.

・Fine powder discharge: Center fine discharge type and Side fine discharge type

・Packing: Standard material is chloroprene, optionally silicone and EPDM are available.

・Auxiliary equipment: raw material feeders, etc.

FAQ

- Is it possible to conduct a performance test?

- We have test machines for all models.

- How many High-Sifters have been sold until now?

- More than 600 machines have been sold.

- Is it possible to obtain a plan drawing that assumes the installation location?

- We will check the customer site, then, discuss the specifications, and create a plan drawing.

- What kind of components are necessary for maintenance?

- In many cases, only wire meshes and packings are necessary to be replaced as the consumable parts.

- Is it possible to export overseas?

- Yes, we have already delivered over several hundreds of units worldwide, including North America, Europe, and Asia.

The machines are also CE-certified for the European market, providing customers with confidence and reliability.