Products

Dearation/Granulation/Pressing

- Mining/Ceramics/Glass

- Toner

- Metal/Battery/Semiconductor

- Foodstuff/Agriculture/Recycle

- Pharmaceuticals/Cosmetics

Roller compactor

Roller Compactor can produce granules from low-bulk-density fine powder without water or any other binders. This process is started from the feed hopper. The feed screw located below the hopper deaerates and put the fine powder into the roll unit to press it. By pressing fine powder, fine powder becomes long strips or flakes. The system is efficient and economical without a drying process. Therefore, energy cost is reduced. Roller compactor can be used for many industries that handle fine powder to produce granules and to improve the handling difficulty.

Features

-

1)Vertical arrangement of rolls promotes effective deaeration and reduces unpressed powder.

2)The amount of fine powder can be kept minimum by setting the breaker to match the desired granule size.

3)Since the screw feeder can be disassembled easily and the breakers are mounted on the roll press separately, machine cleaning is very eacy.

Applications

●Metal compounds

Battery materials, Magnesium oxide, Titanium oxide, Maganese oxide, Iron oxide, Lead oxide, Silver oxide, Carbon, Ferrite,

●Chemical

Melamine resin, Urea resin, Phenolic resin, Epoxy resin, Detergent, Agricultural chemicals, Chemical fertilizer, Toner powder, Powder coatings, Pigments, CMC, Bleaching powder, Plastic additive, Polymer flocculant, Ash, Silica,

●Pharmaceutical

Granules, Fine granules powders, pre-tabletting granules, Granules for filling inside capsule

●Food

Seasonings, instant food powder, supplements artificial sweeteners, flavors,

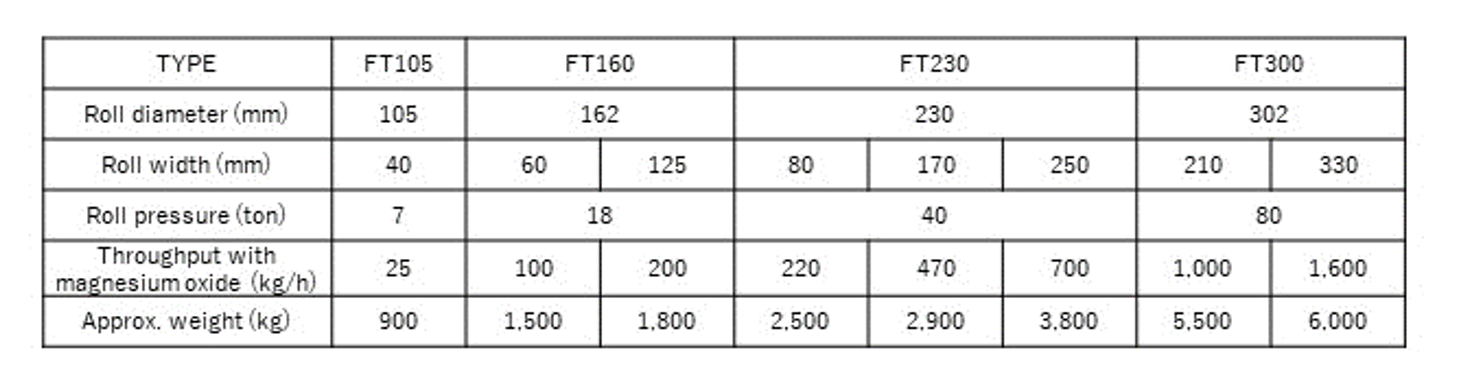

Specifications