Products

Pulverizing

- Mining/Ceramics/Glass

- Toner

- Metal/Battery/Semiconductor

- Foodstuff/Agriculture/Recycle

- Pharmaceuticals/Cosmetics

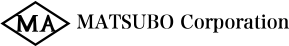

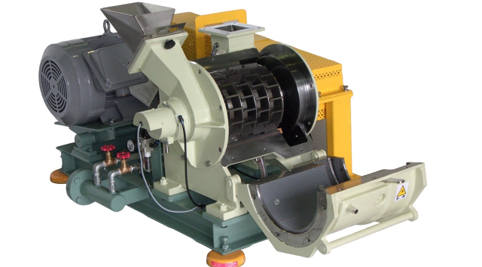

Turbo Mill

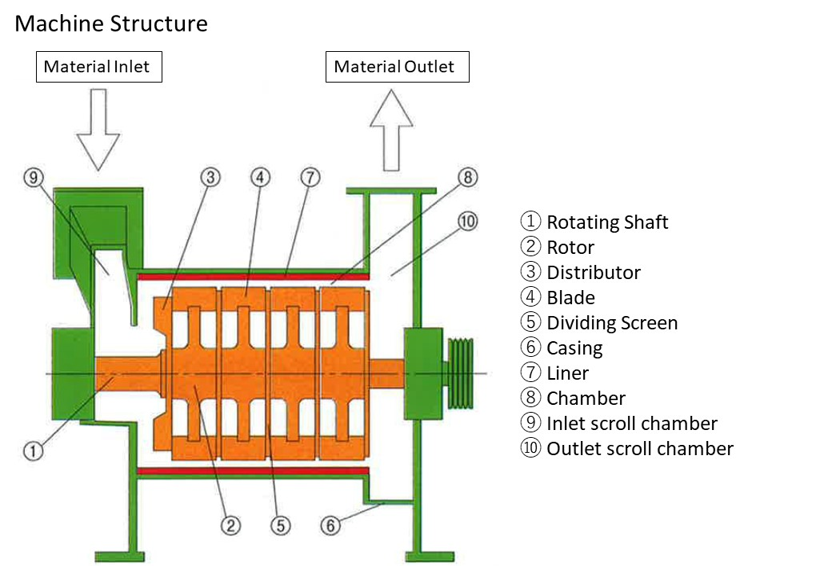

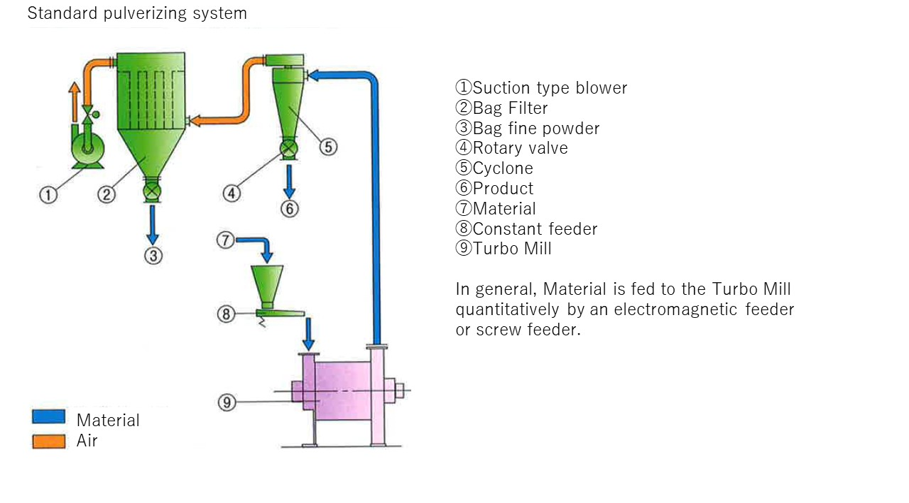

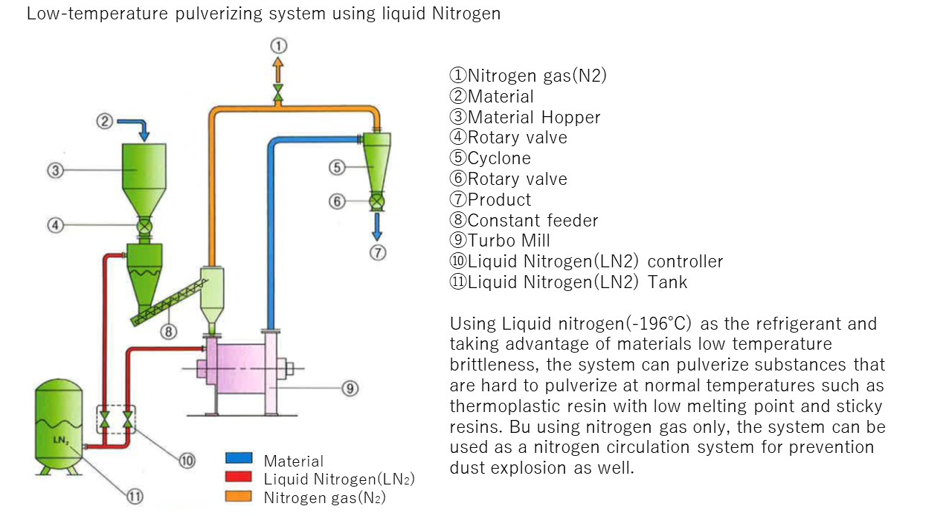

The Turbo Mill is a dry processing mill that goes a step beyond just impacting and shearing. It obtains your desired particle size by the impact from the high-speed rotation of blades and the high-speed vortex flow generated behind them. The Turbo Mill produces less fines than the jet mill resulting in a sharp particle size distribution, and it consumes less energy. A diverse lineup of models is available for just about any application and grinding particle diameter.

Features

-

1.Simple and solid design with no internal screens makes maintenance easy and promises nearly permanent and trouble-free operation.

2.Because of high-speed rotation and the use of more rotor stages, it forms a smaller amount of fine powder compared to comparable products, ontaining a sharp particles size distribution.

3.Energy costs for the Turbo Mill is lower (1/3 to 1/2), and produce less fines than the jet mill pulverization.

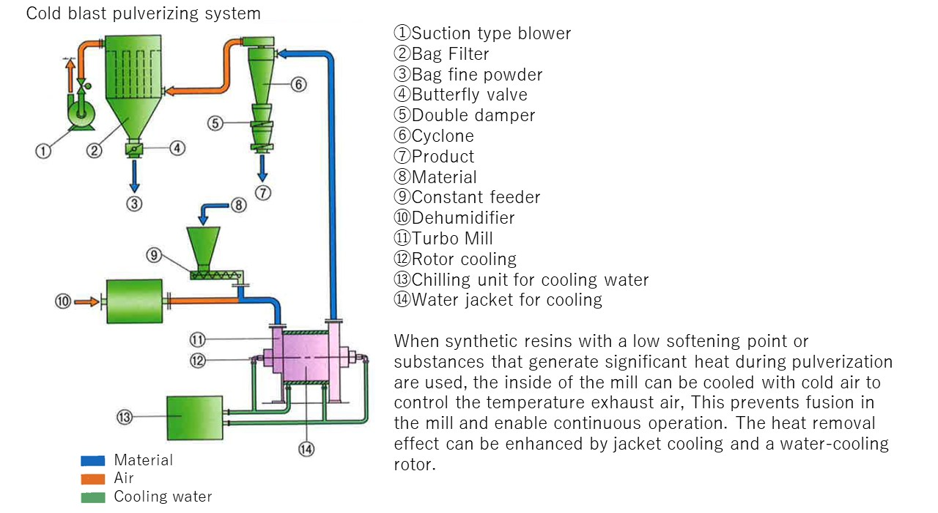

4.Water-cooled rotor (direct cooled rotor) (CR type) is available for heat sensitive raw material (retrofit possible in the existing Turbo Mill).

5.Spherical ground products can be obtained especially for toner.

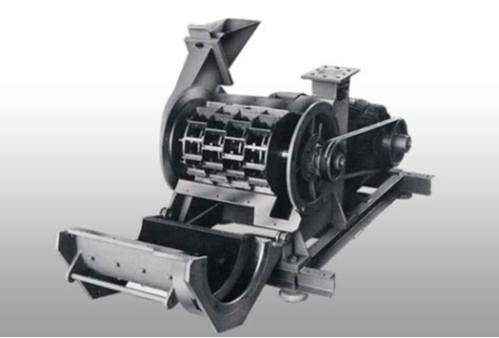

Specifications

Applications

| Sort | Material | Particle size of feed material | Particle size of pulverized sample | Type | Capacity (kg/hour) |

|---|---|---|---|---|---|

| Paint & pigment | Toner (black) | d50:250μm | d50:6.5μm | T400-4RSJ | 45 |

| Toner (color) | d50:190μm | d50:5.3μm | T400-4RSSJ | 30 | |

| Toner (black, for pre-grinding) | 1~4mm | d50:25μm | T400-4J | 100 | |

| Pigment | d50:100μm | d50:6μm | T400-4J | 60 | |

| Powder coatings | 5~20mm(flake) | d50:30μm | T400-3ELJ | 300 | |

| Powder paint slag | d50:1.5mm | d50:10μm | T400-4J | 300 | |

| Chemicals | Chalk wall | d50:250μm | under150μm (85%) | T400-4 | 500 |

| Copper powder | d50:25μm | 5~10μm | T400-4 | 200 | |

| Ammonium phosphate | d50=1.0mm | d50:19μm | T400-4 | 170 | |

| Sodium carbonate | 0.1~0.5mm | d50:16μm | T250-4 | 300 | |

| Electric & electronic Materials | Battery material | d50:20μm | d50:3.5μm | T400-4RSJ | 200 |

| Graphite | d50:450μm | d50:12μm | T400-4J | 300 | |

| Resin | Poly-carbonate | d50:1.0~1.5mm | 357~535μm | T400-4F | 1660 |

| Water absorptive polymer | 2~3mm | d50:2μm | T400-4J | 100 | |

| PVC scrap | MAX 8mm | under 500μm (90%) | T400-4J | 60 | |

| ABS resin | 2~3mm pellet | under 210μm (95%) | T400-4J | 70 | |

| LDPE | 2~3mm pellet | under 177μm (90%) | T400-4J | 60 | |

| PET | Max 5mm | under 105μm (93%) | T400-4J | 130 | |

| Phenolic resin | Max 5mm | d50:18μm | 400-4J | 550 | |

| Fluorine resin | Max 30mm (flake) | d50:30μm | T400-4J | 200 | |

| Melamine resin | 1~10mm | under 75μm (99%) | T400-4J | 250 | |

| Epoxy resin | d50:500μm | d50:4.5μm | T400-4J | 70 | |

| miscellaneous | CMC | d50:105μm | under 75μm (70%) | T400-4J | 50 |

| Cellulose | 5~10mm | d50:40μm | T400-4J | 60 | |

| Wood | 0.5~5.0mm | d50:150μm | T400-4J | 100 | |

| Pulp | 1~10mm | Loosing | T400-4 | 150 | |

| Foods | Agar | under 200μm | under 50μm (97%) | T400-4RSJ | 30 |

| Buckwheat barry | 4~5mm | d50:8.5μm | T400-4J | 480 | |

| Buckwheat chaff | 3~4mm (clacking) | d50:180μm | T400-4J | 60 | |

| Tea | 1~3mm | under 45μm (97%) | T250-4J | 90 | |

| Whear flour | d50:90μm | d50:18μm | T400-4J | 200 | |

| Mixed bran | d50:300μm | under 180μm (80%) | T400-4J | 250 | |

| Rice | 2~3mm | under 63μm (80%) | T400-4J | 350 | |

| Granulated sugar | 1×1×1mm□ | under 75μm (100%) | T400-4J | 500 | |

| Red pepper | 20~50mm | d50:190μm | T400-4J | 500 | |

| Defatted soybeans | d50:85μm | d50:10μm | T400-4J | 200 | |

| Defatted rice bran | d50:300μm | d50:12μm | T400-4RSJ | 80 | |

| Sodium alginate | d50:50μm | d50:15μm | T400-4ESJ | 150 |

Specifications

FAQ

- Is it possible to conduct a performance test?

- We have test machines T-250 and T-400.

- How many Turbo Mill have been sold until now?

- More than 1,000 machinery have been sold.